Samotics

Condition monitoring platform for submerged, borehole, and otherwise inaccessible pumps. Samotics installs hardware in the motor control cabinet to collect voltage and current signals, uses Electrical Signature Analysis to detect mechanical and electrical faults, and provides alerts, root-cause insight, and energy-optimization recommendations for water utilities and industrial operators.

What is Samotics

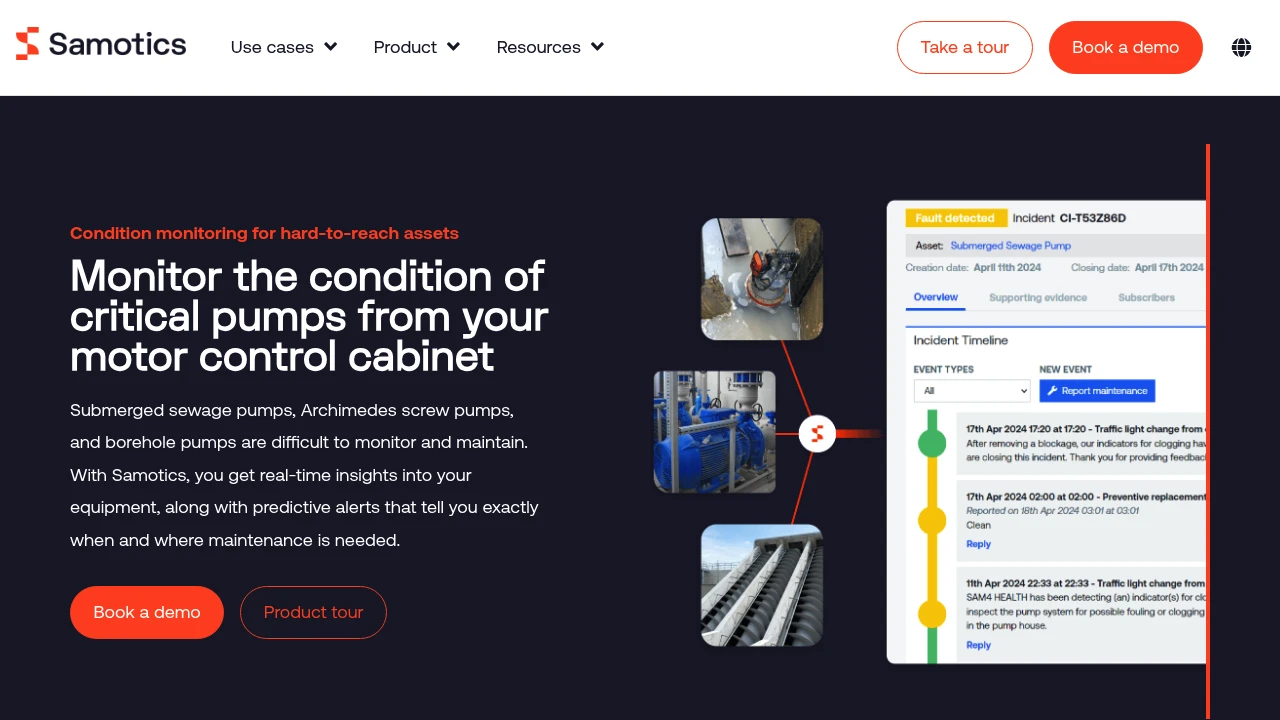

Samotics is a condition monitoring platform focused on hard-to-reach rotating assets such as submerged sewage pumps, borehole pumps and Archimedes screw pumps. The technical approach relies on Electrical Signature Analysis (ESA): sensors installed in the motor control cabinet measure voltage and current signatures from the motor and drive, and algorithms translate those signatures into actionable diagnostics for drivetrain and pump health.

The product family centers on the SAM4 hardware module paired with a cloud platform and a specialist support workflow. SAM4 is designed for installation in the motor control cabinet (MCC) so teams avoid confined-space work and the logistical complications of accessing submerged equipment. Data collection is continuous, and the platform issues predictive alerts and incident reports that include root-cause indicators and recommended next steps.

Samotics targets operations, maintenance, and innovation teams at water utilities and industrial sites with many distributed or hard-to-access pumps. Use cases include early detection of bearing and coupling wear, progressive blockages in sewage pumps, abnormal motor loading that indicates drift from the pump curve, and identification of energy-saving opportunities.

Samotics features

What does Samotics do?

Samotics continuously monitors electrical signals at the motor control cabinet and uses Electrical Signature Analysis to infer mechanical and hydraulic conditions down the line. By analyzing harmonics, current and voltage imbalances, and signature changes over time, the platform identifies issues such as bearing wear, shaft misalignment, cavitation, and developing blockages without needing direct access to the rotating element.

Key technical features include:

- Real-time acquisition of voltage and current from the MCC, with edge processing on the SAM4 device to reduce bandwidth and highlight anomalies.

- Automated diagnostics that classify events (electrical fault, mechanical fault, hydraulic blockage) and provide a severity score and time-to-failure estimate.

- Alerts routed to operators with incident summaries and data evidence (signature plots, timestamps, and suggested corrective actions).

The platform also supports energy analysis. Samotics produces a real-time pump curve and identifies operation outside of Best Efficiency Point (BEP), quantifying energy losses and giving prioritized recommendations to reduce consumption and CO2 emissions. Reports and dashboards are designed for both field technicians and asset managers so information can be actioned by the correct role.

Samotics pricing

Samotics offers flexible pricing tailored to different business needs, from single-site trials to enterprise-scale deployments across hundreds or thousands of assets. Pricing typically depends on the number and type of monitored assets, level of cloud analytics, frequency of specialist-verified alerts, and the chosen onboarding and support package. Samotics commonly offers both monthly and annual billing options and provides volume discounts and longer-term contract pricing for large water utilities and multi-site operators.

Deployment costs usually include one-time hardware and installation charges plus recurring platform and service fees. Typical pricing components are:

- Hardware charge: one-time per SAM4 unit (varies by model and site accessories).

- Platform subscription: monthly or annual fee per monitored asset or per device group that covers data hosting, analytics and alerts.

- Service add-ons: specialist verification of alerts, onboarding consultancy, and bespoke reporting.

For definitive current rates and options for trials, pilots or enterprise procurement, check Samotics' official pricing page. Visit their official pricing page for the most current information.

How much is Samotics per month

Samotics offers competitive pricing plans designed for different team sizes and deployment scopes; monthly billing is available for short-term pilots and operational flexibility. Monthly fees generally cover cloud analytics and alerting on a per-device or per-asset basis and are commonly higher on a per-month basis than equivalent annual contracts because annual commitments usually include a discount.

If you plan a short evaluation, Samotics frequently supports limited-duration monthly subscriptions for trial devices to validate detection performance before committing to a larger rollout. For precise monthly rates for single-device trials or fleet monitoring, consult their official pricing page.

How much is Samotics per year

Samotics offers discounted annual plans for customers who commit to longer-term monitoring and rollout programs. Annual billing typically reduces the unit monthly-equivalent cost and often includes additional onboarding hours, reporting credits, or lower per-asset platform fees.

Large water utilities that deploy at scale generally negotiate multi-year agreements with combined hardware, installation and subscription pricing; these agreements frequently show meaningful savings compared with month-to-month pricing. For exact annual packages and estimates for your asset mix, see Samotics' official pricing page.

How much is Samotics in general

Samotics pricing varies with scope and service level: a small pilot with a handful of SAM4 devices will be materially less expensive than a full network-wide rollout with specialist-verified alerts and enterprise integrations. Expect costs to scale with the number of monitored pumps, the complexity of asset types (borehole vs. surface pump), the required alerting SLA, and integration or custom reporting needs.

Planning a budget should include: Hardware costs: one-off SAM4 units and installation materials; Platform subscription: recurring analytics, storage and alerts; Service costs: onboarding, specialist verification and integration work. For accurate total-cost-of-ownership projections based on your fleet and operational objectives, review their official pricing page.

What is Samotics used for

Samotics is used primarily for condition-based monitoring and reliability engineering of pumps and other rotating assets that are difficult or unsafe to access. Typical applications are in wastewater networks, groundwater abstraction, and industrial facilities where pumps are submerged or located in confined spaces.

Operational use cases include:

- Early detection of developing faults like bearing deterioration, pump blockages, or shaft issues before they cause failure or overflow incidents.

- Reducing unnecessary time-based inspections by replacing calendar-based checks with condition-triggered work orders, which lowers routine inspection costs.

- Prioritizing maintenance visits by severity and root cause so field teams apply resources where they create the most value.

Strategic uses include energy management and decarbonization: Samotics provides pump-efficiency data and recommendations that support energy-reduction programs and regulatory reporting. Innovation teams use monitored data to build digital twins and to validate retrofits or operational changes.

Pros and cons of Samotics

Samotics offers a focused solution for monitoring hard-to-reach pumps, but there are trade-offs to consider when evaluating fit for your operation.

Advantages:

- Non-intrusive monitoring: sensors are installed in the motor control cabinet, avoiding direct exposure to submerged equipment and lowering safety and access costs.

- Detects a broad range of fault modes using Electrical Signature Analysis, including mechanical, electrical and hydraulic anomalies.

- Provides energy-optimization guidance and a visible pump curve to quantify inefficiencies and prioritize corrective actions.

Limitations and considerations:

- ESA infers mechanical and hydraulic conditions from electrical signals; in some complex root-cause cases supplemental on-site inspection or secondary measurements (vibration, pressure) may still be required to confirm corrective actions.

- Upfront costs include hardware and installation, and total cost scales with the number of monitored assets; procurement for very large rollouts often requires longer negotiation cycles.

- Integration with existing SCADA/asset management systems requires planning; while Samotics offers integration options, custom integrations may require professional services.

Samotics free trial

Samotics commonly supports pilot deployments to validate detection algorithms and operational impact before a full rollout. A typical free or low-cost pilot will include a small number of SAM4 devices installed at representative sites, basic onboarding, and access to the analytics dashboard so teams can review alerts and incident reports.

Pilots focus on proving three outcomes: detection accuracy for the faults of interest, reduction in unnecessary inspections, and identification of energy-saving opportunities. Samotics’ onboarding team typically performs an initial technical assessment to select assets and configure the units, then runs the pilot with monitoring and reporting to demonstrate value.

To request a pilot or trial, contact Samotics through their site; they often align pilot scope with specific business goals such as preventing overflows or reducing emergency call-outs. See Samotics’ platform overview and trial options for current pilot programs and onboarding details.

Is Samotics free

No, Samotics is not a free product for full deployments. However, the company routinely offers limited pilots or trials for prospective customers to evaluate detection performance and business benefits before committing to a paid rollout. These pilot arrangements are commonly time-limited and scoped to a small number of devices.

For long-term monitoring, Samotics charges for hardware and ongoing platform services; negotiated enterprise agreements are typical for large utilities. For current pilot availability and trial eligibility, consult their platform overview.

Samotics API

Samotics provides APIs and integration options to exchange data with third-party systems such as SCADA, CMMS (Computerized Maintenance Management Systems), and asset management platforms. APIs typically expose diagnostics, alert histories, incident reports and energy metrics so teams can feed Samotics outputs into existing workflows and ticketing systems.

Integration capabilities commonly include RESTful endpoints, webhook-based alert forwarding, and CSV/JSON export for reporting. For enterprise customers, Samotics also supports secure integrations with single sign-on (SSO) and role-based access control to comply with internal access and compliance policies.

If you require deep systems integration or custom data models, Samotics offers professional services to configure the API, set up data pipelines and validate data accuracy in the target system. Check Samotics’ platform integration documentation for specifics on supported endpoints and authentication methods.

10 Samotics alternatives

Paid alternatives to Samotics

- Grundfos Remote Management — A cloud-based monitoring and fleet-management solution designed by pump manufacturer Grundfos; it provides telemetry, alarms and lifecycle data primarily for Grundfos equipment and mixed fleets.

- Emerson AMS Suite (Plantweb) — Broad condition-monitoring software with machine diagnostics, vibration and electrical monitoring integrations, and enterprise asset management connectivity for industrial environments.

- Bently Nevada (GE) — An established condition monitoring portfolio focused on rotating machinery diagnostics, vibration monitoring, and machinery protection systems with strong analytics.

- Schneider Electric EcoStruxure Asset Advisor — Offers remote monitoring and predictive analytics integrated into Schneider’s EcoStruxure framework and targeted at utilities and industrial customers.

- Siemens MindSphere (Asset Performance Management) — Industrial IoT platform with analytics toolsets for asset health, suitable for large-scale deployments and integration with Siemens automation hardware.

- SKF Enlight ProCollect — SKF’s route-based and continuous condition monitoring solutions with a strong focus on bearings, lubrication and mechanical diagnostics.

- ABB Ability Condition Monitoring — Provides equipment-level and fleet-level monitoring services with analytics and advisory services for rotating machines.

Open source alternatives to Samotics

- Grafana (with InfluxDB/Prometheus) — Open-source visualization and time-series stack that can be configured to collect electrical signal-derived telemetry and create dashboards, alerts and historical analyses.

- ThingsBoard — An open-source IoT platform that supports telemetry ingestion, rule chains for alerting, and device management; can be adapted for condition monitoring with custom analytics.

- Node-RED — Flow-based integration tool that can orchestrate sensor data ingestion, lightweight edge processing, and forwarding to databases or dashboards for monitoring purposes.

- Apache NiFi — Open-source dataflow tool for ingesting and routing telemetry from distributed devices to analytics engines; useful when building a customized condition-monitoring pipeline.

- OpenTelemetry + Prometheus — A telemetry collection framework that, when combined with Prometheus, provides metrics collection and alerting for custom monitoring solutions.

Frequently asked questions about Samotics

What is Samotics used for?

Samotics is used for condition-based monitoring of hard-to-reach pumps and motors. Its system detects electrical and mechanical faults, identifies developing blockages and provides energy-efficiency insights so teams can prioritize targeted maintenance and reduce emergency repairs. The approach is particularly useful for submerged sewage pumps, borehole pumps and other assets where direct access is difficult.

How does Samotics detect pump blockages?

Samotics detects blockages by analyzing changes in electrical signatures of the motor. Blockages alter load characteristics and current harmonics; the platform’s algorithms recognize these patterns and generate alerts with severity and suggested next steps. In many cases this enables intervention before an overflow or environmental incident occurs.

Does Samotics require installing sensors on the pump itself?

No, Samotics is designed to be installed in the motor control cabinet rather than on the pump. By measuring voltage and current at the MCC, the system infers drivetrain and hydraulic conditions downstream without the need for confined-space access or crane-assisted installations.

Can Samotics integrate with SCADA or CMMS systems?

Yes, Samotics supports integrations with SCADA and CMMS via APIs and webhook forwarding. Exported diagnostics, incident reports and alerts can be routed into existing asset-management workflows so organizations maintain a single source of truth for maintenance planning.

Is Samotics accurate at fault detection?

Samotics publishes high detection accuracy in field trials—examples indicate detection rates around the mid-90s percent for many pump fault types. Actual accuracy depends on asset type, installation quality, baseline signal characteristics and the variety of monitored fault modes; pilots are recommended to quantify performance for a specific fleet.

Why choose Electrical Signature Analysis (ESA) rather than vibration sensors?

ESA allows condition monitoring from the motor control cabinet, avoiding direct access to submerged or hard-to-reach rotating components. While vibration monitoring provides direct mechanical signals, ESA is non-intrusive, lower-cost to deploy at depth, and effective at detecting many drivetrain and hydraulic issues when installed and calibrated correctly.

When should I run a pilot with Samotics?

Pilot projects are recommended when introducing condition-based monitoring or validating expected outcomes. A pilot helps verify detection accuracy for your asset mix, quantifies inspection and emergency-repair reductions, and provides concrete energy-savings estimates before committing to a broader rollout.

Where does Samotics operate and who uses it?

Samotics works with water utilities and industrial operators globally, with engineering and operations clients in Europe and beyond. The platform is used by maintenance, operations and innovation teams that manage distributed pump fleets including wastewater networks and groundwater abstraction schemes.

Does Samotics offer on-site installation support?

Yes, Samotics provides onboarding, technical assessment and installation guidance, and can supply certified installers or partner with in-house teams. Onboarding typically includes asset selection, shipment of hardware, installation verification and initial tuning to ensure correct diagnostics and alerting thresholds.

How much does Samotics cost per device?

Samotics offers competitive pricing plans designed for different fleet sizes and support levels; per-device subscription fees and one-time hardware costs are common components. Costs vary with asset type, required SLA and volume discounts—visit Samotics’ official pricing page for up-to-date rates and pilot options.

Samotics careers

Samotics recruits across product engineering, field services, data science and customer success roles related to condition monitoring and industrial IoT. Roles typically require a mix of electrical engineering, signal processing, software development or systems integration experience. Candidates interested in product development should expect to work on embedded measurement systems, cloud analytics and algorithm tuning for real-world pump fleets. See Samotics’ careers and hiring information for current openings and application instructions.

Samotics affiliate

Samotics partners with system integrators, OEMs and consultants in the water and industrial sectors to expand distribution and installation capabilities. While a public consumer-style affiliate program is uncommon in industrial monitoring, Samotics does operate reseller and partnership channels; prospective partners should contact Samotics’ commercial team to discuss partner tiers and referral arrangements.

Where to find Samotics reviews

Independent reviews and case studies are available through utility case studies, industry publications and Samotics’ own site where they publish customer testimonials and detailed deployment reviews. For third-party perspectives, search for water-industry conference presentations or professional forums where water utilities discuss pilot outcomes and vendor comparisons, and consult case studies on Samotics’ site for documented performance examples.